Prefabricated Steel Structure Building as Warehouse/Workshop/Factory

Basic Info

Model No.: PTW

Product Description

Model NO.: PTW Standard: GB, ISO Forming: Hot-Rolled Steel Member: Steel Column Carbon Structural Steel: Q235 Application: Steel Workshop, Steel Structure Platform, Steel Fabricated House Roof Insulation: Steel Sheet or Sandwich panel Eaves Gutter: PVC Door: Steel Rolling Door Delivery Time: 40 Days After Received The Down Payment Painting: Epoxy Zinc Rich Primer, 100um Specification: custom made HS Code: 9406000090 Type: H-Section Steel Trademark: Special Purpose Steel, PTH Connection Form: Bolt Connection Type of Steel For Building Structure: High-Strength Steel Residential Wall Structure: Wallboard Size: Designed as Per Customer′s Requirement Material: Steel Structure, Sandwich Panel Downspout: PVC Pipes Crane: with or Without, as Per Required Welding: Muti-Spot Welding Transport Package: Use Intergrated Steel Rack, Flat Packing Origin: Shaoxing, Zhejiang, China Part 1:Company Profile

TAG:CE BV Approved Hot Sale Steel Structure for Workshop

Part 2:Product Description

1, Options

Application:

all kinds of steel buildings, metal buildings, modular house, Steel Frame for warehouse, workshop, garage,garden,shed etc, steel beams, other riveting and welding parts.

Building Type: Single slope, double slope, Single span, double-span, Multi-span,single floor, double floors!

Tailored to your needs:

We can also make and develop new parts according to customers' drawings and detailed dimensions.

Design Parameters:

size: width X length X eave height, roof slope.

Wind speed(KM/H), Snow load (KG/M2), Demands for doors and windows

Crane(if have), Crane span, crane lift height, max lift capacity, max wheel pressure and min wheel pressure!

2, Structural System

Base: Cement and steel foundation bolts

Column and beam: Q345 or Q235 steel , all bolts connection! Straight cross-section or variable cross-section!

Bracing: X-type bracing made from angle, round pipe etc.

Type C or Z purlin: Size from C120~C250, Z180~Z250

Surface treatment: Two layers of Anti-rust Painting!

Material Q345 or Q235 Steel Production Process

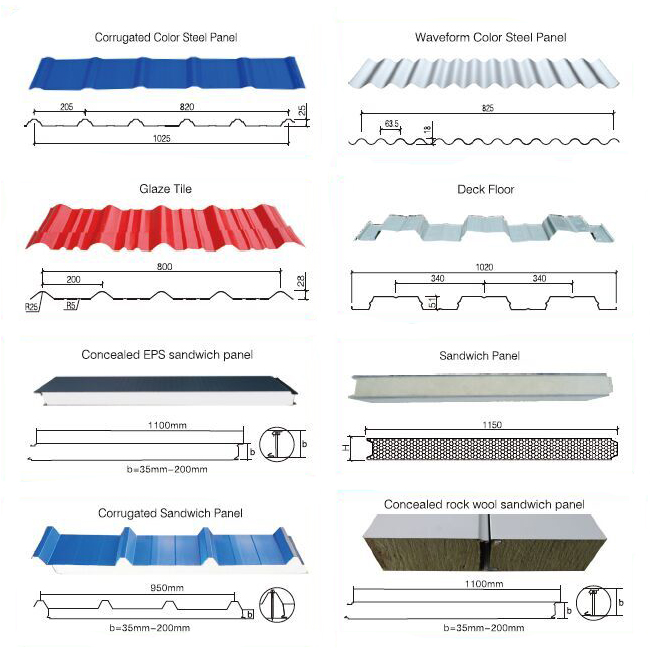

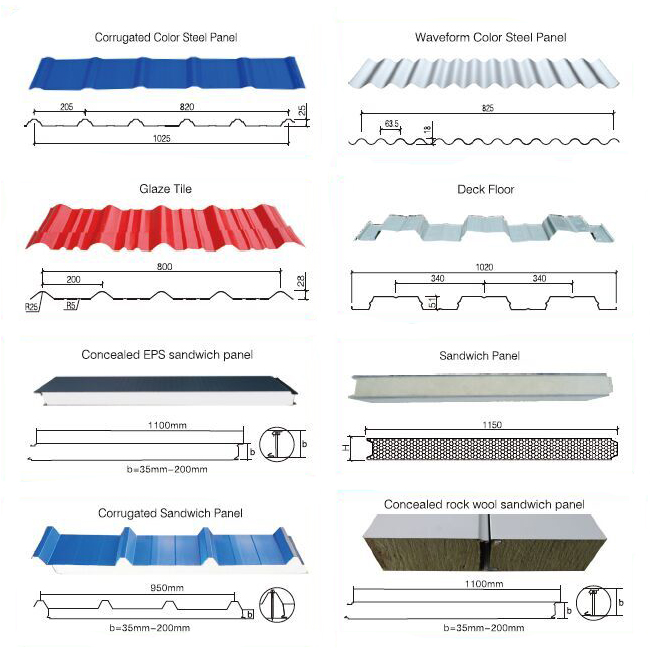

3, Roof and Wall Panel

Single colorfull corrugated steel sheet0.30~0.63mm thick, (1150mm wide), or sandwich panel with EPS, ROCK WOOL, PU etc, insulation thickness around 50mm~100mm

Part 3: Packing

Main steel frame without packing load in 40' OT, roof and wall panel load in 40' HQ!

Part 4: Installation

PTH provides customers with one-stop integrated housing solution including installation and operation. We have 3 options for on-site installation according to the customer's specific situation. Firstly, we offer installation instructions and installation video. Secondly, we assign the installation team for the project. Finally, we send professional engineer to guide the local installation team.

FAQ

1. Do you provide on-site installation service?

1) Only large projects provide installation services

2) General projects, we can provide Installation guide service based on customers' request.

3) Installation supervision charge standard: 150USD/day, customer should responsible for the travel fee, accommodation, translation fee, and ensure staff's health and safety.

2. What's your delivery time?

Salesman will confirm the time accordingly, large order should communicate with order management department in advance. Normally, delivery time is 45days after receive deposit. Large order delivery time should be arranged separately.

3. How to control the quality of your product?

a. quality of the design: think about possible problems in advance and provide a high quality design solution.

b. quality of the raw material: choose the qualified raw material

c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

4. How to deal with quality problems?

Warranty is 3 years. Within the warranty period, PTH will responsible for all quality problems caused by production.

5. If there is a clear service life of your products? If have, how long?

Under conventional climate and environment, steel structure whole building 10 years, main structure 15 years, protecting system 10 years.

6. What designs do you have in different climates (How can the products adopt to different climates)?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anticorrosive coating.

Contact Details

Tel:86-571-83513988 / 18057525090

FAX:86-571-83513787

Office: Room 1601, Unit 3 of No. 1 Building, Dikai Plaza, # 471 Jincheng Road, Xiaoshan District, Hangzhou

Factory: Beiliu Road, Binhai Development Zone, Shaoxing City, China

Contact us if you need more details on Steel Structure Building. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Prefabricated Steel Building、Prefabricated Workshop. If these products fail to match your need, please contact us and we would like to provide relevant information.

TAG:CE BV Approved Hot Sale Steel Structure for Workshop

Part 2:Product Description

1, Options

Application:

all kinds of steel buildings, metal buildings, modular house, Steel Frame for warehouse, workshop, garage,garden,shed etc, steel beams, other riveting and welding parts.

Building Type: Single slope, double slope, Single span, double-span, Multi-span,single floor, double floors!

Tailored to your needs:

We can also make and develop new parts according to customers' drawings and detailed dimensions.

Design Parameters:

size: width X length X eave height, roof slope.

Wind speed(KM/H), Snow load (KG/M2), Demands for doors and windows

Crane(if have), Crane span, crane lift height, max lift capacity, max wheel pressure and min wheel pressure!

2, Structural System

Base: Cement and steel foundation bolts

Column and beam: Q345 or Q235 steel , all bolts connection! Straight cross-section or variable cross-section!

Bracing: X-type bracing made from angle, round pipe etc.

Type C or Z purlin: Size from C120~C250, Z180~Z250

Surface treatment: Two layers of Anti-rust Painting!

Material Q345 or Q235 Steel Production Process

3, Roof and Wall Panel

Single colorfull corrugated steel sheet0.30~0.63mm thick, (1150mm wide), or sandwich panel with EPS, ROCK WOOL, PU etc, insulation thickness around 50mm~100mm

Part 3: Packing

Main steel frame without packing load in 40' OT, roof and wall panel load in 40' HQ!

Part 4: Installation

PTH provides customers with one-stop integrated housing solution including installation and operation. We have 3 options for on-site installation according to the customer's specific situation. Firstly, we offer installation instructions and installation video. Secondly, we assign the installation team for the project. Finally, we send professional engineer to guide the local installation team.

FAQ

1. Do you provide on-site installation service?

1) Only large projects provide installation services

2) General projects, we can provide Installation guide service based on customers' request.

3) Installation supervision charge standard: 150USD/day, customer should responsible for the travel fee, accommodation, translation fee, and ensure staff's health and safety.

2. What's your delivery time?

Salesman will confirm the time accordingly, large order should communicate with order management department in advance. Normally, delivery time is 45days after receive deposit. Large order delivery time should be arranged separately.

3. How to control the quality of your product?

a. quality of the design: think about possible problems in advance and provide a high quality design solution.

b. quality of the raw material: choose the qualified raw material

c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

4. How to deal with quality problems?

Warranty is 3 years. Within the warranty period, PTH will responsible for all quality problems caused by production.

5. If there is a clear service life of your products? If have, how long?

Under conventional climate and environment, steel structure whole building 10 years, main structure 15 years, protecting system 10 years.

6. What designs do you have in different climates (How can the products adopt to different climates)?

Strong wind region: improve the wind-resisting ability of the internal structure.

Cold region: increase the thickness of the wall, or use good insulation material, improve anti-pressure ability of the structure.

High corrosion region: use corrosion resistant material, or paint anticorrosive coating.

Contact Details

Tel:86-571-83513988 / 18057525090

FAX:86-571-83513787

Office: Room 1601, Unit 3 of No. 1 Building, Dikai Plaza, # 471 Jincheng Road, Xiaoshan District, Hangzhou

Factory: Beiliu Road, Binhai Development Zone, Shaoxing City, China

Contact us if you need more details on Steel Structure Building. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Prefabricated Steel Building、Prefabricated Workshop. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Steel Structures Building > Others Steel Structures Building

Premium Related Products

Other Products

Hot Products

ISO Certificated Modular Customized Heavy Steel Bridge for TransportationHigh Quality Standard Prefabricated Container House as Modular BuildingPrefab High Quality Steel Structure AccomadationWell Designed Steel Structure Warehouse (PTWW)High Quality Cheap Steel Structure for WarehouseLight Steel Frame Villa with Glass Curtain WallLow Cost Steel Structure Storage BuildingManufactured Heavy Steel H Section for BridgeConstruction Design Light Steel Structure as Prefab HotelPrefabricated Steel Structure Exhibition HallSteel Pipe Truss Structure for Stadium Stand ShedHigh Rise Heavy Steel Strucutre Industrial BuildingLarge Span Steel Structure Aircraft HangarCE BV Approved Hot Sale Steel Structure for WorkshopPrefabricated Steel Building for Steel Structure WarehousePrefabricated Steel Structure Frame Workshop