Wheat Flour Milling Plant With Steel Structure Workshop

Basic Info

Model No.: 10-500T/24H

Product Description

PINGLE Group-Integrated Milling Solutions Provider!

Part 1:

Brief Introduction of Pingle Group's Complete Milling Engineering Ability

Hebei Pingle Flour Machinery Group Co., Ltd., established in 1991, is a group enterprise specialized in grain machinery project manufacturing and installation with diversified business.

The company's main business is to produce and operate various types of wheat, corn, cereals and other grain milling machinery complete sets of equipment, and undertakes 100-1000t Steel Structure complete sets of equipment turnkey project, at the same time, our company also provides breweries with professional large and medium-sized complete sets of equipment. The product market covers all major grain producing areas in China and exports to more than 40 countries and regions such as Ethiopia, Zambia, Kenya, Tanzania, Mozambique, Uganda, Egypt, Algeria, South Africa, India, Brazil, Pakistan, Vietnam, Russia, Tajikistan, Uzbekistan, Iran, Canada and so on. The export volume, sales volume and market share of the products rank at the forefront of the grain machinery industry in China. PINGLE Group is a professional manufacturer with complete models, large scale, good quality, reputation, excellent service and high technology content in the grain machinery industry.

After 28 year`s development and growth, PINGLE Group has established a good cooperative relationship with more than 10,000 customers in the global market, providing our customers with professional equipment and technical services. PINGLE has become a well-known manufacturer of grain machinery engineering equipment at home and abroad. In 1999, Pingle acquired the right of private enterprises to import and export; in 2002, PINGLE passed the ISO9001:2000 international quality management system certification, and adopted ERP information management and 6S standardization management; in 2013, PINGLE were recognized as national high-tech enterprises and provincial enterprise technology center.

Hebei Pingle Group's efforts have been highly appraised by governments at all levels and widely praised by the public. He has won the honorary titles of "Top Ten Brands of Grain Machinery in China", "Famous Brand Products of Hebei Province", "Leading Enterprises of Industrial Cluster in Hebei Province", "Honest Enterprises of Hebei Province", "Quality-benefit Enterprises of Hebei Province", "Top 50 Enterprises of Industry in Shijiazhuang City", "Advanced Units of Foreign Trade Export in Shijiazhuang City", "AA Enterprises of Shijiazhuang Customs".

PINGLE Group Head office in China

Part 2:

PINGLE Group Complete Set Wheat Flour Milling Plant Technical parameter table:

| Model

| Final Products

| Total Power (KW) | Power consumption(KW/h)

| Capacity (ton of wheat per 24H)

| Workshop dimension (L×W×Hm)

|

| 120t | Special purpose flourGradeⅠ flourGrade Ⅱ flourStandard flour(co-production)

| 480 | 70-74 | 120 | 40×7.5×18.5 |

| 140t | 610 | 68-72 | 140 | 45×12×20.6 | |

| 160t | 700 | 68-72 | 160 | 48×12×20.6 | |

| 200t | 810 | 65-71 | 200 | 53×12×23.3 | |

| 250t | 1180 | 65-71 | 250 | 65×12×30.1 | |

| 300t | 1310 | 65-71 | 300 | 70×12×30.1 | |

| 400t | 2020 | 68-72 | 400 | 107×12×31.4 | |

| 500t | 2420 | 68-72 | 500 | 124×12×32.1 |

Technical characteristics of products:

1: The proportion of the building cost in the total factory construction fee is greatly reduced by using this design method, which not only relieves the pressure of concrete building construction for users, but also reduces the self-weight of factory building, so the cost of foundation treatment and foundation construction is very low because of the adoption of steel structure factory building.

2: This product has the new characteristics of combining equipment with workshop. The steel structure workshop and Grain Processing Machinery can be built and installed simultaneously. It has the advantages of fast and convenient installation, fast construction speed, short construction period, and can recover investment in the shortest time.

3: The equipment layout is reasonable, the structure is compact, the area occupied is reduced, and the investment is saved; the internal use of high-quality section steel, the storage bins for original wheat and cleaned wheat adopts rectangular steel bar, the wheat bins outside wall can be placed with thermal insulation layer and the outer wall adopts color steel plate structure. The overall structure is rigorous and the appearance is neat, coordinated and beautiful.

4: The Seismic capability is better than brick-concrete structure factory building.

5: This series of milling units can be easily removed. The flour mills can be moved as a whole with high reused value, and can create higher economic benefits.

In a word, this series of units is the best investment way for large and medium-sized flour mills.

This series complete set of equipment is consisted by high square plan sifter, new type pneumatic roller mill and other flour milling equipment. The overall design is novel and unique, the flour milling equipment is advanced, the process is reasonable, it can produce grade powder, special powder, and can also be co-produced. This design method of Steel Structure Building is originally design in PINGLE. It is an innovation of engineering technicians of PINGLE Group. This design fills a gap in our country, can fully meet the production needs, and has higher economic benefits. The company sells the plant and equipment as a whole is an important feature of this series of products. This design method relieves the pressure of building the plant for the users, saves the time and funds for the customers to the maximum extent, and enables the users to realize the ideal investment mode with less investment and quick effect.

Part 3:

PINGLE Flour Mill Plant Engineering Performance in Overseas and Domestic Market

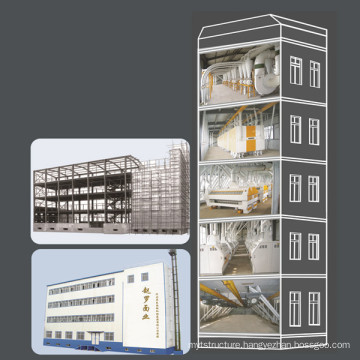

Uganda 160T/24H Wheat Flour Milling Plant

Zhaoluo Flour Mill 500T/24H Wheat Flour Milling Plant(Hebei Province)

For More Project Performance, Pls click PINGLE Group Website

Contact us if you need more details on Wheat Flour Mill. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wheat Flour Making Machinery、Wheat Flour Milling Plant. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Turnkey Flour Milling Plant > Steel Structure Flour Milling Plant